Aluminum-plastic packaging machine how to operate 新葡萄最新官网(中国) standard?

Hits:8950 Date:2016/11/25

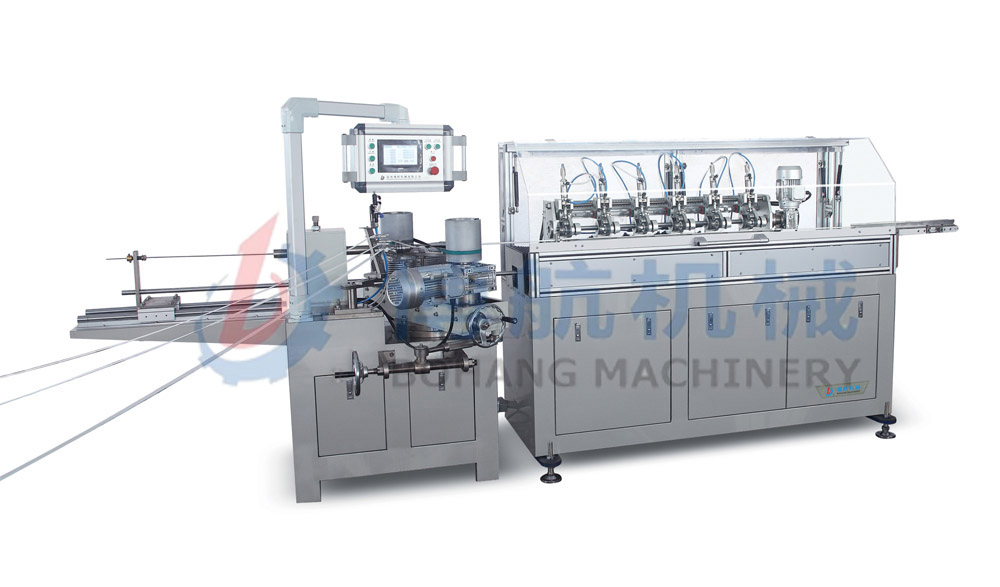

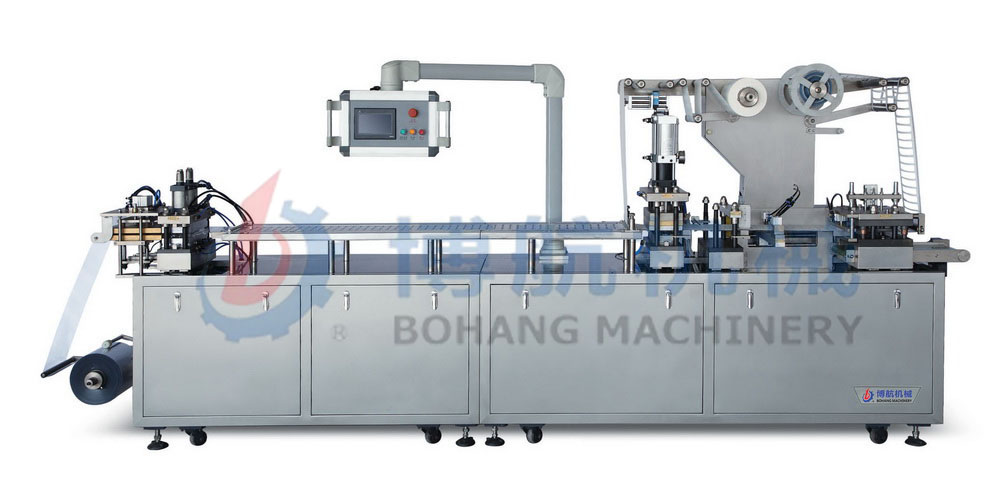

Aluminum-plastic packaging machine is mainly used for packaging capsules, tablets and other solid pharmaceutical packaging machine, using the form of heating, is the smallest of the most advanced models at home and abroad. Then the aluminum-plastic packaging machine how to regulate the operation?

1, the green light is on, forming up and down with the heat sealing two heating switches were pulled to the "ON" position, the first table, temperature controller control forming temperature, generally preset 90C˚ and 100C˚, Temperature control, preset temperature 120C˚-140C˚ up and down, molding and sealing temperature controller preset temperature, depending on the specific circumstances.

2, put down the roller from the pressure roller, forming the heating plate temperature in place, and then open the host, the first plastic PVC molding, forming bubble and hot sealing mold hole position, pay attention to heat sealing mold seat down with heat sealing mold foil , Aluminum foil will lead to punching. Observe the plastic (refers to the board surface has been formed PVC) whether to move around the offset. If there is a bias should be adjusted from the cited pressure roller seat transfer from the cited direction.

3, if the foil around the biasing, adjustable transfer roller handle under the hand wheel. If the front and rear deviation adjustable box movement.

4, heat sealing blanking properly after the opening of the feeder gate, the drugs (tablets capsules, sugar clothing) into the feeding room, if a small amount of artificial fill can fill, fill the grain when the primary Note: roller pressure roller Rolling hand and hook broken aluminum foil, the other forming bubble to the edge of the roller, there are missing grain, do not barely fill, fill holes are not allowed, the drug was brought into the 新葡萄最新官网(中国) serious impact synchronization, light this seal in the aluminum foil Sticky mold, to set machine processing.

5, due to increase the weight of drugs, aluminum foil tension and the process of gradual changes in temperature range, may lead to forming and heat sealing is not synchronized phenomenon, lead or lag, first check whether the plastic PVC and aluminum foil vaginal septum, and then machine fine-tuning institutions. Fine-tuning mechanism in the mold forward and backward, because of its adjustment distance or box before and after the adjustment. So before the boot should be placed in a neutral position, can move forward and backward, can also be used to move the front box adjustment, the correct move, the forum to finish after a dozen versions of the right, so not finished, do not Chaos tune to transfer to.

6, the quality of the heat sealing plastic foil (bonding evenly firm and straight) from the temperature or pressure, reticulate board to prove that the degree of flatness, if a bad heat seal, the general should be the temperature, the general temperature, low pressure, , The most adjustment coil pressure.

7, blanking bias, cut off with the layout offset, stop the body will be transferred to adjust the box, you can adjust the mold shift.

8, in the daily operation of knowledge, for the operation must understand the structure of the machine principle, by the cam drive jack block wheel, up and down stroke, fixed position die cover die, blister bad state, note the next mold or heat sealing To the only point, tighten the column nut, do not pay attention to the words prone to failure, the mandrel roller needle roller killed phenomenon, eliminate the method.

1, the green light is on, forming up and down with the heat sealing two heating switches were pulled to the "ON" position, the first table, temperature controller control forming temperature, generally preset 90C˚ and 100C˚, Temperature control, preset temperature 120C˚-140C˚ up and down, molding and sealing temperature controller preset temperature, depending on the specific circumstances.

2, put down the roller from the pressure roller, forming the heating plate temperature in place, and then open the host, the first plastic PVC molding, forming bubble and hot sealing mold hole position, pay attention to heat sealing mold seat down with heat sealing mold foil , Aluminum foil will lead to punching. Observe the plastic (refers to the board surface has been formed PVC) whether to move around the offset. If there is a bias should be adjusted from the cited pressure roller seat transfer from the cited direction.

3, if the foil around the biasing, adjustable transfer roller handle under the hand wheel. If the front and rear deviation adjustable box movement.

4, heat sealing blanking properly after the opening of the feeder gate, the drugs (tablets capsules, sugar clothing) into the feeding room, if a small amount of artificial fill can fill, fill the grain when the primary Note: roller pressure roller Rolling hand and hook broken aluminum foil, the other forming bubble to the edge of the roller, there are missing grain, do not barely fill, fill holes are not allowed, the drug was brought into the 新葡萄最新官网(中国) serious impact synchronization, light this seal in the aluminum foil Sticky mold, to set machine processing.

5, due to increase the weight of drugs, aluminum foil tension and the process of gradual changes in temperature range, may lead to forming and heat sealing is not synchronized phenomenon, lead or lag, first check whether the plastic PVC and aluminum foil vaginal septum, and then machine fine-tuning institutions. Fine-tuning mechanism in the mold forward and backward, because of its adjustment distance or box before and after the adjustment. So before the boot should be placed in a neutral position, can move forward and backward, can also be used to move the front box adjustment, the correct move, the forum to finish after a dozen versions of the right, so not finished, do not Chaos tune to transfer to.

6, the quality of the heat sealing plastic foil (bonding evenly firm and straight) from the temperature or pressure, reticulate board to prove that the degree of flatness, if a bad heat seal, the general should be the temperature, the general temperature, low pressure, , The most adjustment coil pressure.

7, blanking bias, cut off with the layout offset, stop the body will be transferred to adjust the box, you can adjust the mold shift.

8, in the daily operation of knowledge, for the operation must understand the structure of the machine principle, by the cam drive jack block wheel, up and down stroke, fixed position die cover die, blister bad state, note the next mold or heat sealing To the only point, tighten the column nut, do not pay attention to the words prone to failure, the mandrel roller needle roller killed phenomenon, eliminate the method.

On a message:Not available Next information:Paper-plastic packaging machine which has the advantages and characteristics

Related News

Small aluminum-plastic blister packaging machine features which?

[ 2016/11/25 ]Small aluminum-plastic blister packaging machine is composed of what?

[ 2016/11/25 ]Paper-plastic packaging machine which has the advantages and characteristics

[ 2016/11/25 ]Aluminum-plastic packaging machine how to operate 新葡萄最新官网(中国) standard?

[ 2016/11/25 ]

Your Current Location:

Your Current Location: