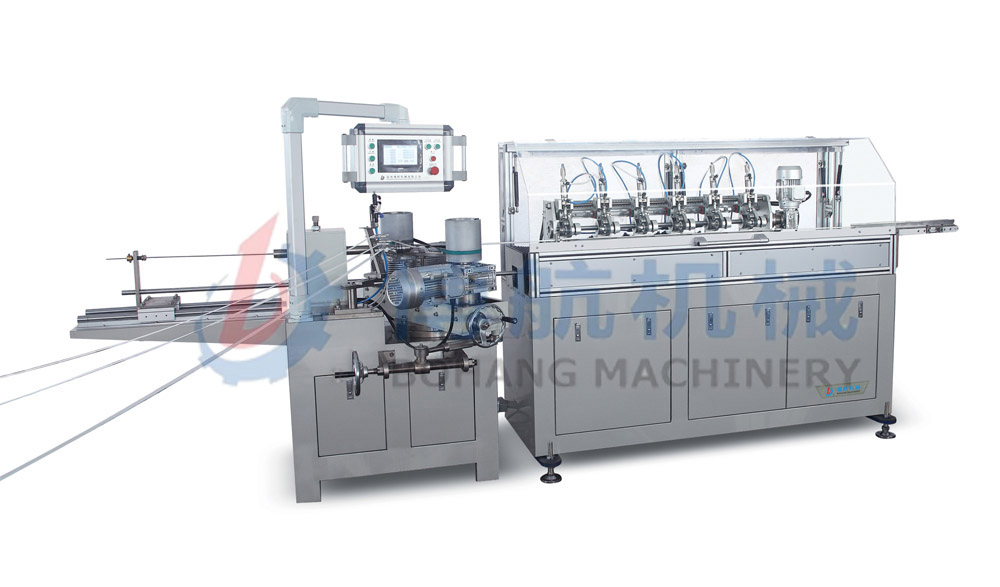

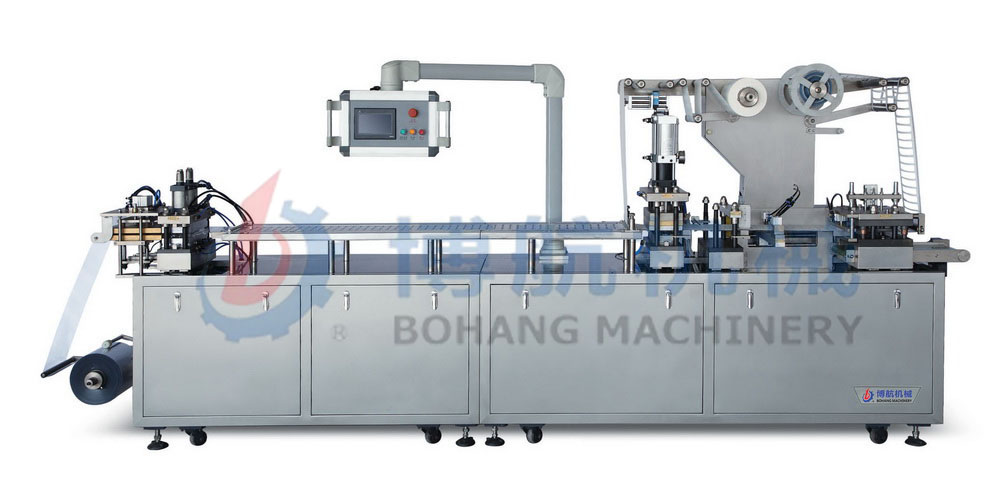

Product Details

1. Working principle:

The automatic bag sorting machine can be used alone in production or connected with the cartoning machine to complete the whole sorting process of irregular stacked materials from centralization to dispersion to sequential placement. After the irregularly stacked materials are poured into the storage bin, the bin conveyor belt acts to transport the materials to the low-speed roller. The equipment sends the materials out of the bag sorting machine one by one through the operation of low, medium and high speed rollers. The delivered materials will enter the cartoning machine for transportation according to the form or order required for packaging or stacking to complete the next process of cartoning.

2、 Performance characteristics:

● Integrated design of material storage, feeding and bag management, simple structure, compact and generous appearance;

● Overall sealing, safe operation.

● Integrated large capacity storage bin, convenient for feeding;

● The bottom of the silo is equipped with a conveyor belt to facilitate feeding and avoid material residues.

● The feeding and conveying roller is driven by multiple groups of servo motors, and the speed is adjusted through the feedback signal of the photoelectric sensor. The control is accurate and the bag sorting speed is fast.

● Fully automatic arrangement is realized through servo control, and multiple servo systems realize orderly stacking of materials in a regular manner, and the process is stable and controllable;

● The whole process is decentralized, sequential and stacked without manual intervention;

● The number of bag handling machines can be increased or reduced according to the needs of speed by combining multiple methods, and the single machine can also complete the finishing process;

● Multi servo system control, high speed and accuracy, convenient operation and high degree of automation;

● The equipment body is made of 304 stainless steel, meeting GMP requirements;

3、Technical parameters:

| Project | Specific parameters | remarks |

| Maximum speed | 300 bags/minute | It is related to the material size, and the actual material testing speed shall prevail |

| Bag specification | Length ≤ 180mm; Width ≤ 100mm | |

| Total power | 5.5kW | |

| Power Supply | AC220V 50/60Hz | |

| Overall dimensions | 2250(L)×950(w)×1560(H) | |

| Total weight | 300Kg |

Your Current Location:

Your Current Location: